If the quality of the fiber & yarn are not properly identified & known to the people who are engaged with pricing with foreign buyer then proper …

- Date : 11 & 18 April 2025

- Time: 9 am to 5 pm

- Last Date of Registration: First come first serve basis

- Dedicated Course Trainer

- Contact: +88 01761-026502, 01734-211085

- Venue : House of Textile Today

Background:

Textile Industry in Bangladesh is passing through many challenges at different stages. To survive & to achieve regular growth at business, Factory owners & entrepreneurs need efficient personnel at every sections of fabric productions . Fiber & yarn are core of fabric. If the quality of the fiber & yarn are not properly identified & known to the people who are engaged with pricing with foreign buyer then proper pricing can not be done. On the other hand, the people who are on the top position of knitting & dyeing should have proper knowledge on fiber & yarn to maintain the fabric Quality. Everyone who is engaged with fabric production must need proper knowledge on fiber and yarn to produce quality fabric.

Now a days, new technologies are introducing at a frequent rate to the textile Industry for producing Yarn from fiber. If the new technologies are not properly well known to the people who are working with the production department then the best result cannot be achieved. So to meet Buyers demand & new taste we have to be familiar with the new technologies. One of the main targets of Textile Today will be to make the participants familiar with the new technologies & information as Textile Today is trying to establish themselves as the Knowledge Leader.

Course Contents:

Part: 1

- An introduction to the textile fibers.

- Cost effectiveness and consumption of different types of fabric produced from different fibres all around the globe.

- Machineries used for producing different types of fibre.

- Differences Challenges & final benefit of producing different types of fibre.

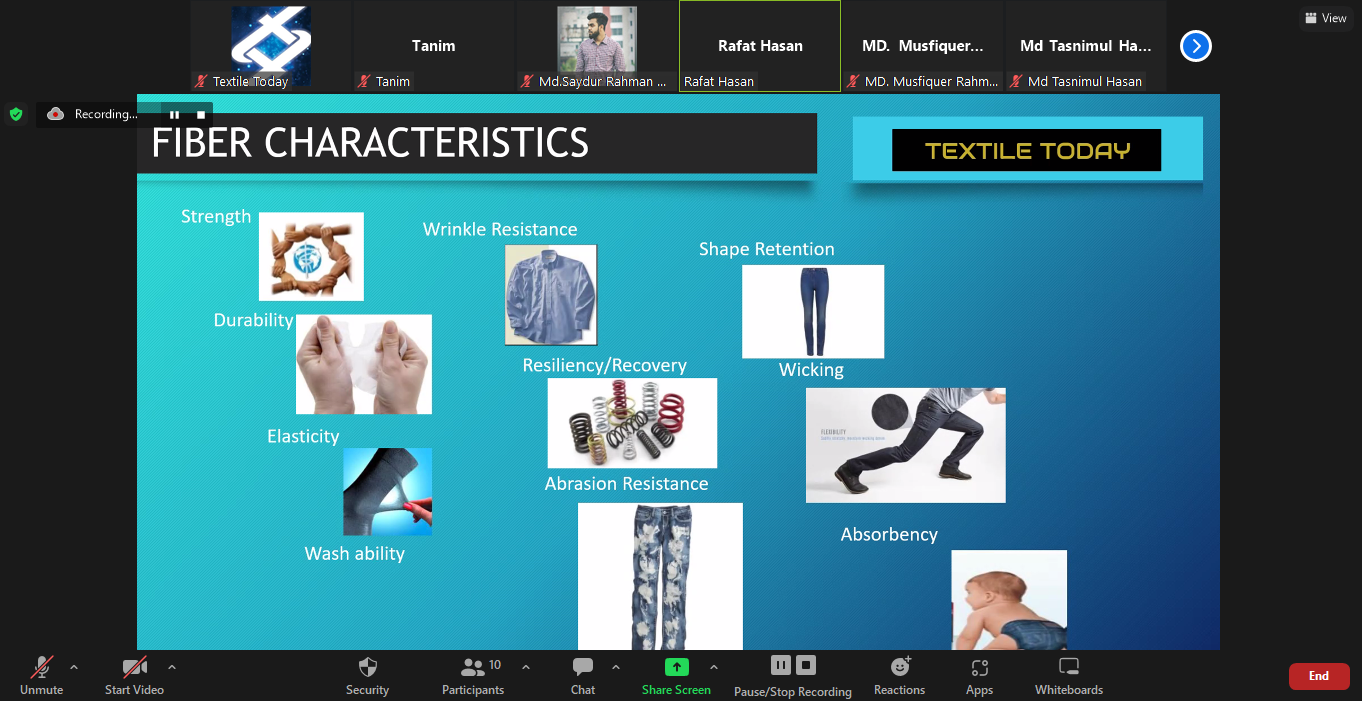

- General characteristics. Nature, physical structure of textile fibers.

- Textile Fibers Classification (natural, man-made).

- Changes in the production and consumption of textile fibers.

- Analytical presentation of each fibre type (cellulosic fibres, protein fibres, manmade fibres based on natural polymers, synthetic fibres). An emphasis is given on the morphology and physical characteristics of natural fibers and the spinning methods of the man-made fibres.

- Textile fibre identification (methods and testing equipment’s).

- Physical properties and characteristics of Textile fibers.

- Methods and devices for determining the physical, mechanical, chemical properties.

- Uses and requirements of the appropriate fibre blending for the achievement of the desired final product for specific use.

- Effect of fibre properties and characteristics on the final textile product.

- Laboratory testing for the identification of Textile fibers. Determination of physical, mechanical and chemical properties (fibre length, fineness, diameter, morphology, linear density, moisture content, tensile strength).

Part: 2

- Discussion on different yarn properties.

- Flow path of yarn manufacturing & discussion on different stages of spinning machineries like Blowroom ,Carding ,Drawframe simplex, ringframe etc.

- Discussion on Synthetic Spinning. Secrets of Melt Spinning , Dry Spinning , wet spinning

Spinning Calculations to run a spinning mill. - Detailed discussion on Different spinning technologies used in Modern spinning Industry of Bangladesh like Ring , Rotor,Compact, Airjet ,Core spun ,inject, syro etc with required animation videos

- Discussion on Spandex yarn & impact on fabric quality

- Different types of Yarn properties

Part: 3

- Raw material of knitting (Yarn specially synthetic)

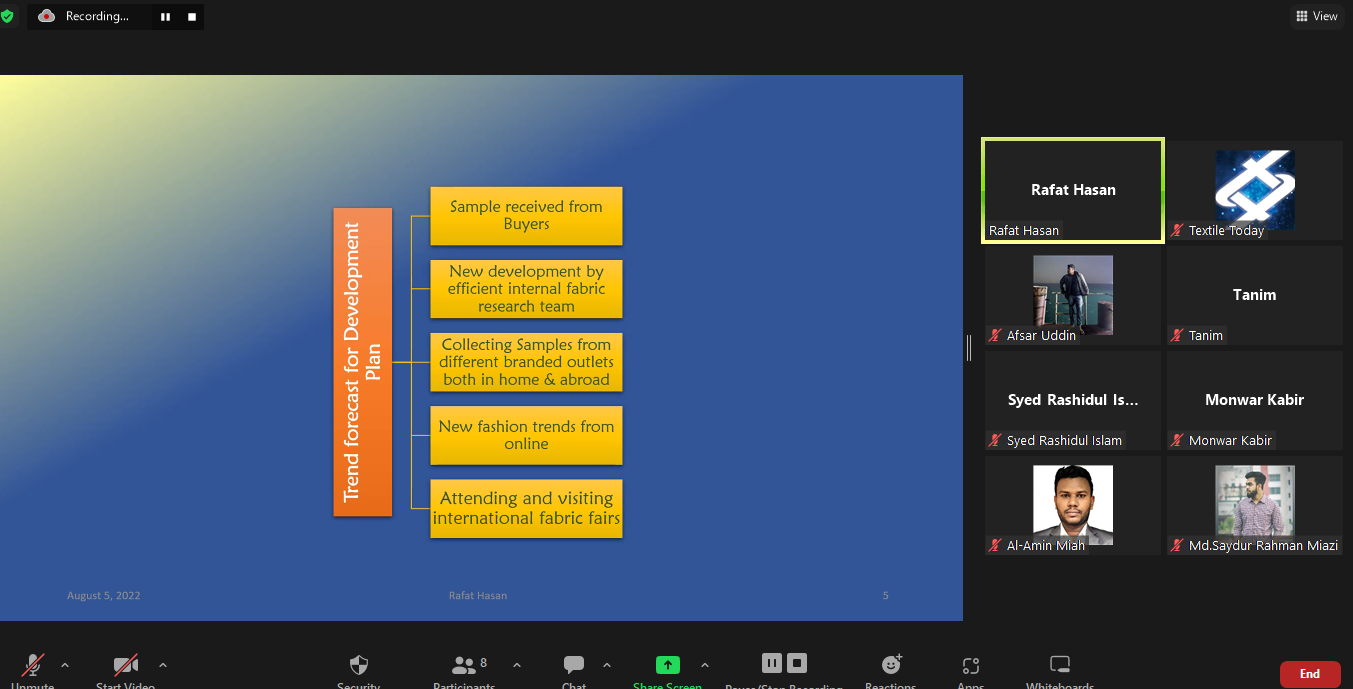

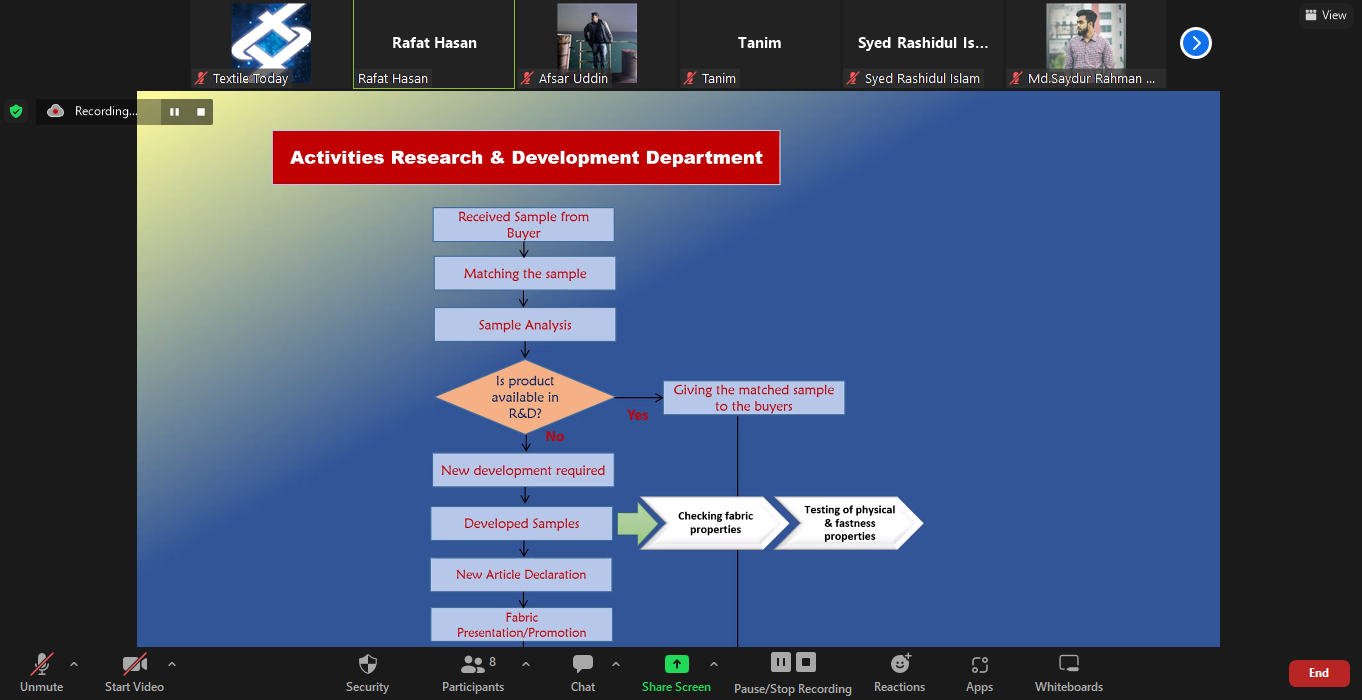

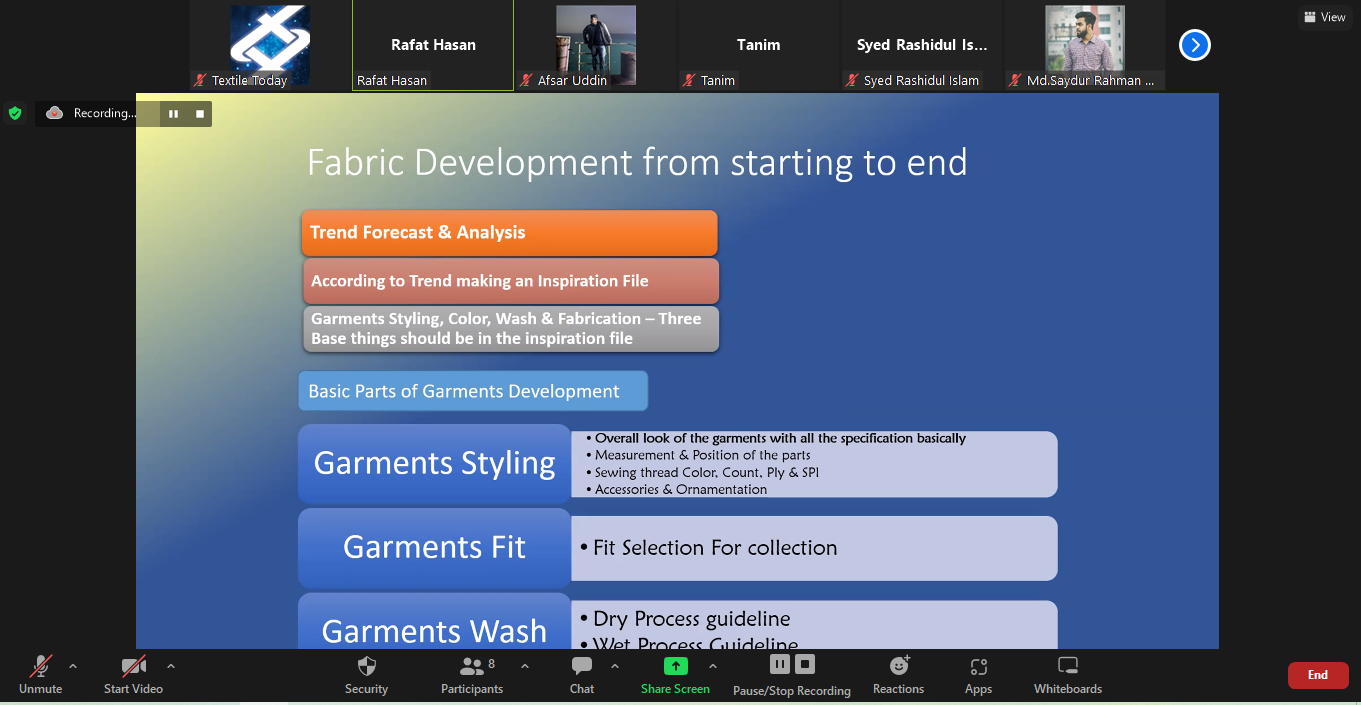

- Research and Development of knitted fabrics

- Category of developing knitted fabrics

- Technical knowledge and Analytical ability

- Scope of Synthetic fabric and its future in BD

- Challenge of Fabric costing and fabric price with Vietnam, China, and Cambodia.

- Utilization of Manpower & Talent

- Concept of knitting Quality

- Application of Q.C Circle, 5S & LEAN in knitting as well as textile.

- Risk Analysis of competitive market (Price of raw material, machine & others).

- Automation of knitting

- Future scope of business (Warp Knit & Seam less) in Bangladesh

- Growth of Recycle and sustainability

Part – 4:

- Research & development of Woven Fabric.

- New development of woven fabric

- Trend of time.

- Process involved in manufacturing different kinds of woven fabric .

- Machinery used to developed & manufactured of new fabrics.

- Technology in woven fabric.

Course Fee :

For individual training modules: 5900/- (Five thousand Nine Hundred taka only)

Course Fee :

BDT 5900 /- ( Five Thousand Nine Hundred Taka Only )

Mentors Profile

Engr. Rafat Hasan Chowdhury

Director Huetech Yarn Limited Sole Agent of Huafon Spandex Yarn and Fabric Sourcing Engr. Rafat […]

Learn more

List of Successful Certificate Receivers

1st Batch

Displaying 1 – 14 of 14

Name Company

Md Fakhruddin

Envoy Textiles Limited

Syed Jobayer Ahamad

Butex

Md. Tanvir Hasan Mahmud

Butex

Riasat Zaman

Butex

Md. Mahir Asif

Butex

Md. Tawfiq Elahi

Butex

Md. Provat Hossain Raj

Butex

Iqbal Hossain

Butex

Mohammad Nasir Uddin

Garments & Textile Consultants

Mahfuzur Rahman

Ben Chemicals BD

Md. Sanuardi Mithun

Mukashi Associates BD Ltd.

Waliullah

GP

Md. Rokon Uddin

APS Group

Md. Tauhidul Islam

Liberty Associates

2nd Batch

Displaying 1 – 7 of 7

Name Company

Shahriar Islam

Butex

Tamim Bin Rafiq

AUST

Md. Zahirul Hoque

Primasia

Shudhangsha Kumar Mondol

APS

Md. Rifatur Rahman Miazee

NITER

H.M Mahbub Rabbani

Thermex

Md. Farhan Shariar

NITER

3rd Batch

Displaying 1 – 10 of 10

Name Company

Habib Monzur Hasan (Bappu)

KRB International

Bashir Ahmed Sifath

AUST

S.M. Faiyaj

AUST

Md. Mehedi Hassan

NITER

Mokarimul Hoque

AUST

Sudipta Shekhor Roy

NITER

Sayeem Sarker

AUST

Ibrahim Khalil

AUST

SK Sadman Sakib

BUFT

Fahim Ahmed Hazbi

BUFT

4th Batch

Displaying 1 – 9 of 9

Name Company

Prince Al Farabi

BUFT

Tanvir Sujoy

DIU

Sharoze Kabir

Businessman

Farhan Shahriar

NITER

Mohammad Asaduzzaman

DIU

Tasmim Jahan Muna

Home Economics

Akil Mahadi

Niter

Nisha Mutsuddi

Barisal Textile Engineering College

Aminul Islam

Professional

5th Batch

Displaying 1 – 29 of 29

Name Company

Taufik Hasan Tonoy

Northern Tosrifa Group

Nur Farzana Chowdhury

Mohammad Tanvirul Hasnat

NITER

Shah Jahid Majumder

Shyamoli Textile Engineering College

Md Aminul Islam

TM Sourcing

Ayon Sadman

BUFT

Abu Sayed Rafi

JUST

Mohammad Ishaque

BUTEX

Md. Sadman Sakib

Bangladesh University of Textiles

MD. Asadullah AL Galib

PTEC

Sm tausif

Ctec

Abdullah Al Mansur

Textile Today

Md. Hashanur Banna Rafi

Pabna Textile Engineering College

S.M. ASHIK ABEDIN

CTEC

Md.Sakib Al Montasir

BUTEX

Faujia Mushtari

Md. Morshed Ali

NITER

Mushfiq Ahmed

CTEC

Antu Roy Chowdhury

Textile Today

Abdul Kader Jilane

Textile Today

Md Abdullah Al Jaman

Textile Today

Md. Abu Hasan

BUFT

Rajath Roy

Daffodil International University

Istiak Ashraf

Tth

Mowdud Ahmed

MBSTU

Samun Al Mujahid

D I U

Fahmida Islam Lamiya

Textile talent hunt 2020

Md.Fazle Rabby

BGMEA University of fashion & Technology

Jash Kankaria

PMS

6th Batch

Displaying 1 – 6 of 6

Name Company

Mustafa Al Ajmi

SV Pittie Sohar Textiles

Md. Shiful Islam

Mahmud Fashion Ltd (Mahmud Group)

Mahmudul Hasan

MD. AL-IMRAN MASUD

Amanat shah fabrics ltd

Mahdi Mahmud

Union Group

Muhammad Umar Faruq

FD Corporation

7th Batch

Displaying 1 – 9 of 9

Name Company

Al-Amin Miah

NZ Fabrics Limited

Sudipta Bain

UTTARA UNIVERSITY

Afsar Uddin

BGMEA University of Fashion & Technology

Md. Moshiur Rahman

Pisces Corporation Ltd.

Syed Rashidul Islam

Laundry Industries Limited (Envoy Group)

Md Tasnimul hasan

Butex

Mohammad Emadur Rahman Shakil Khan

Lyric Industries(Pvt.)Ltd

Md shajib

Hams garments limited

Monwar Kabir

Vertex RMG Division

8th Batch

Displaying 1 – 12 of 12

Name Company

Mahmodul Hasan

BUBT

Shihab Rahman

BUFT

Touhiduzzaman Tonmoy

BUFT

Suchen Dewan

BUBT

Abir Afnan

Lalmatia Mohila College

Mizanur Rahman

Sinfa Quality Garments

Mr. Nimran

Delco

Mr. Ratul

Ecotex

Abdullah Bishal

BUTEX

Fakhrul Islam

BUFT

Shakil Khan Tanim

Professional

Jahid Hasan Rakib

Butex

9th Batch

Displaying 1 – 12 of 12

Name Company

Nusrat- E-Noor (Annana)

BUBT

Noor-E-Nabi (Ridoy)

BUFT

Sajjad Hossain Khandaker

BUFT

Masia Sahjabin

BUFT

Md, Nafis Kamal Alif

BUTEX

Shahriarul Islam

BUTEX

Abdullah Al Quraish

Dekko Garments Ltd.

Fahima Islam

Al Muslim Group

Habibur Rahman

Business partner

Md. Owes Kuruni Sabuj

Green Pacific Textile

Some Previous Clicks

1st Batch

2nd Batch

3rd Batch

8th Batch

9th Batch