Production planning and control (PPC) is of great importance for the competitive position of manufacturing firms. For over thirty years a …

- Date: 21st & 28th January 2022

- Time:9:00 AM - 5:00 PM

- Last Date of Registration: First come first serve basis

- Dedicated Course Trainer

- Contact: +88 01734 211085

- Venue : House of Textile Today

Production planning and control (PPC) is of great importance for the competitive position of manufacturing firms. For over thirty years a large number of computer assisted PPC systems have been on offer, most of them based on the well-known MRP logic. Since these systems often lead to unsatisfactory results, a number of new concepts for PPC systems have been developed. In this paper we first describe the traditional PPC concept and its critique, then we review the new PPC concepts which are available for practical application (workload control, MRP II, OPT, JIT-Kanban, progressive figures) together with OR models which are relevant to these new concepts.

Production is planned using a long-term, medium-term or short-term view. Long-term views focus on the major decisions a company makes that influence capacity, whereas short-term views focus more on using more efficiently what a company already has. Medium-term views focus on adjustments, such as hiring, firing, layoffs, increasing inventory, or expecting back orders. Typically, companies have separate production plans for the different time horizons. While a company can focus its efforts on a particular horizon, even to the exclusion of the others, it is beneficial to maintain a focus on the long term, even if that focus is broad. For example, a company focused on increasing profit margins in the short term might neglect to reinvest some of those profits–a bad idea for any business in the long term.

Learning Outcomes: –

- To understand the Concept, Definition and Terminology related to PPC

- To learn the Role of PPC Department and Planner Duties & Responsibilities and KPI

- To learn the Industry specific Planning Software & Solutions-Digital Technology

- To Learn How to make Production Plan and Control / Monitor it for Achievement

Program Outlines: –

Day-1

Concept, Definition & Terminology

- Product, Production & Productivity / Efficiency

- Plan & Planning

- Control & Controlling

- Planner Duties & Responsibilities and KPI

Production Planning & Control

- Industry Specific Focus & Application – Apparels & Textiles

- Composite Manufacturer of Apparels – Vertically or Horizontally Integrated

- Order-Project, Lead Time and TNA: – Time & Action-Critical Path – Network Diagram

Making Production Plan in Apparels Industry

- Basic IE concepts (SMV formation)

- Capacity Planning

- Order Planning

- Resources Planning

- Production Scheduling

- Garments Production Planning & Control

Production Planning Software & Technology

- Gannt Chart Based Planning

- Popular Planning Software & Technology in The Industry – Fast React, Datatex – MCM & MQM

- Briefs of Industry Specific Planning Software & Technology – DATATEX: NOW, MCM & MQM for Apparels & Textiles Manufacturing Industry

Day-2 (Implementation)

- Factory capacity Plan

- Style wise (Basic, semi critical, Critical, Hard)

- Efficiency wise.

- Arrange Order based on Factory capacity.

- Style wise – a) Basic Qty – 60 % (Percentage will be changed on factory category)

- b) Semi critical – 25 %

- c) Critical -15 %

- Sewing line loading plan

- Segregate item wise line.

- Based on shipment date

- Make build up plan item wise.

- Lead time allocation (TNA Plan)

- Knitting plan

- Dyeing & Finishing plan (Finish fabric)

- Cutting plan

- Printing or embroidery plan

- Sewing plan

- Finishing plan

- Knitting plan

- Count selection by technical team.

- Yarn booking follow up.

- Knitting machine allocation based on fabric category.

- Follow up fabric delivery date.

- Dyeing & Finishing plan (Finish fabric)

- Fabrics in house follow up.

- Set batch program priority wise.

- Start dyeing machine capacity and fabric category wise.

- Fabric deliveries follow up.

- Cutting plan

- Start cutting date wise.

- Send cut panel to print or embroidery.

- Printing or embroidery plan

- Chemical in-house before print start date.

- Print start and send it to for input.

- Sewing plan

- Accessories in house before line input.

- Layout preparation by IE and technical team.

- Consider learning curve.

- Achieve build up plan.

- Finishing plan

- Finishing start based on priority.

- Ready goods for inspection.

Course Fee :

Training Through Zoom Online : 3000/- (Three Thousand Taka Only)

Course Fee :

BDT 3000 /- ( Three Thousand Taka Only ) ( Online )

Mentors Profile

DHARMENDU DAS SAJAL

Textile Technologist / Apparel & Dye-house expert Bangladesh / RMG & Textiles Experienced & […]

Learn more

Engr. Azim Mohammad

Lead Consultant (Panacea Private Consulting)

Lead Consultant (Panacea Private Consulting)

Learn more

Moshiur Rahman Palash

Deputy Manager (Planning & Coordination dept.), Northern Tosrifa Group (NTG)

Learn more

List of Successful Certificate Receivers

1st Batch

Displaying 1 – 7 of 7

Name Company

Khadiza Akter Mitu

Butex

Iqbal Hossain

Butex

Md. Tanvir Hasan Mahmud

Butex.

Syed Jobayer Ahamad

Butex

Md. Khairul Ahsan

APS Group

Mahmudul Hussain

Ashraful Alam

2nd Batch

Displaying 1 – 9 of 9

Name Company

Mahbub

Rasik-Ul-Latif

C&A

Md. Shamsuzzaman

Manami Fashions Ltd..

Murad

Akib Bin Saleh

AUST

Iqbal Hossain

BUTEX

Kaiday Azam

Tanvir Alam

Abdulla Al Mamun

Snowtex outerwear Ltd.

3rd Batch

Displaying 1 – 12 of 12

Name Company

Kazi Shafiqur Rahman

N2N Sourcing

Mahbub Rabbani

Tharmex Group

Sajjad Hossain

Julfiqar Moyeen Ayon

Tamishna Group

Abdullah Al Hadi

Kaniz Fashion

Ontu Roy Chowdhury

South East University

Habib Monjur Hasan

Nazmus Sakib

Fakir Fashion

Shohag Moitra

Meghna Group

Md. Sabuj

Masco

Mr. Hannan

Utha Group

Arifur Rahman

Esquire

4th Batch

Displaying 1 – 10 of 10

Name Company

Md. Tanvir Hassan

Dekko Isho Group

Tauhid Ahmed

Shinhan Apparel Co., Ltd

Md.Anik hasan

Silken sewing ltd

Nayan Bhowmick

Ovs Hong kong sourcing Ltd.

Shaiful Islam

Nassa Group

Kabir Hossain

Epic Group

Musabbir Hasan

Thianis Apparels Ltd.

Mohammad Tanvir Rahaman

Fariha Knit

Sozol

SKETC

Sayed Mostafa Ali Rajib

Asst. Manager (IE & Planning)

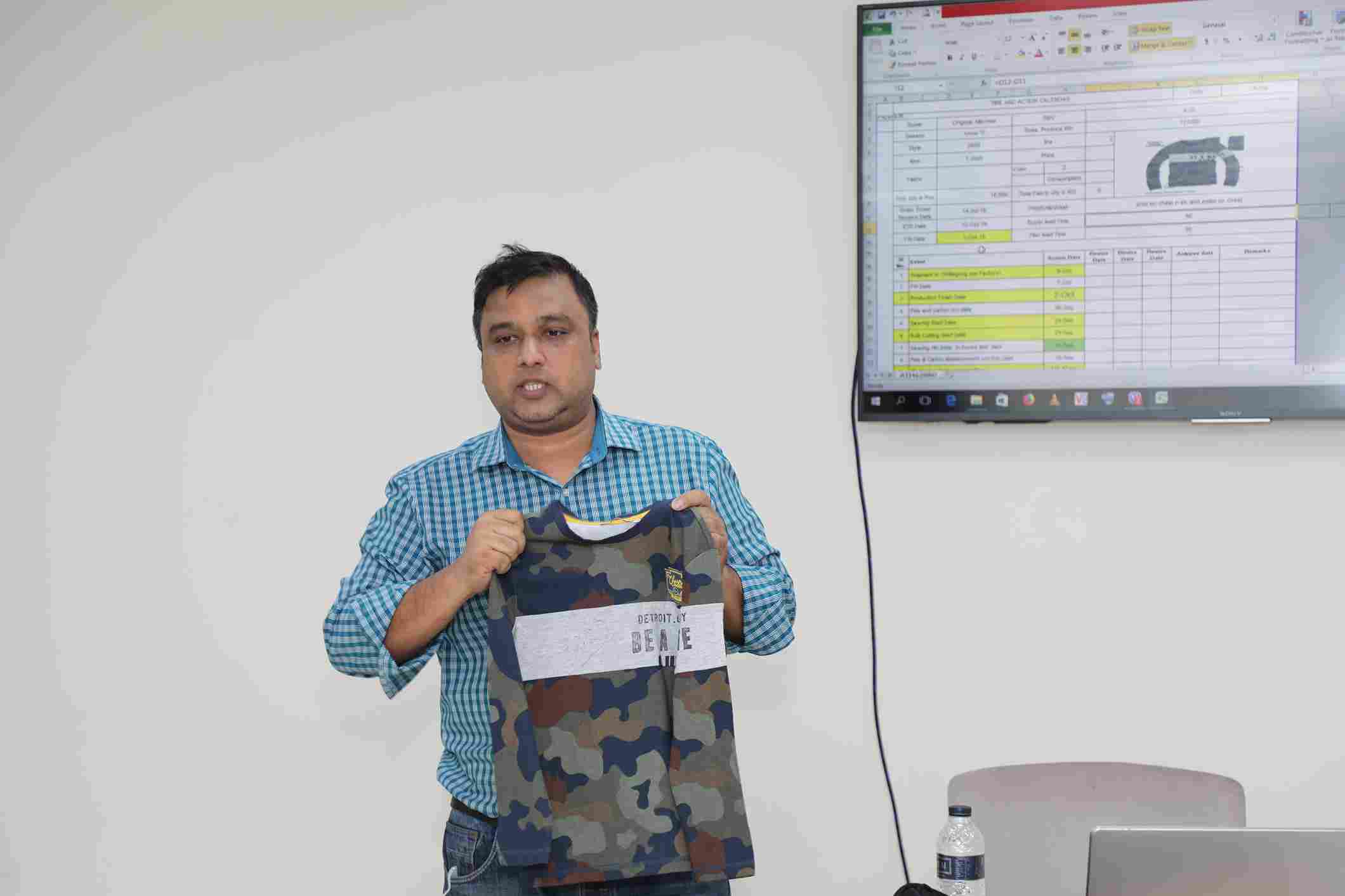

Some Previous Clicks

1st Batch

2nd Batch