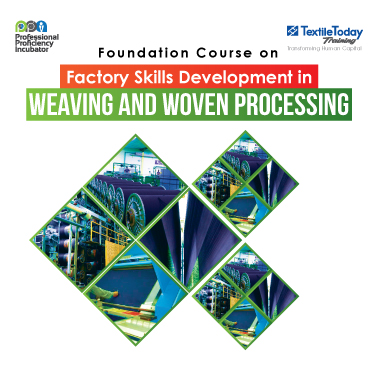

Weaving is a method of textile production in which two distinct sets of yarns or threads are interlaced at right angles to form a fabric or cloth …

- Date: 6 & 13 December 2024

- Time: 9:00 AM - 5:00 PM

- Last Date of Registration: First come first serve basis

- Dedicated Course Trainer

- Contact: +88 01734 211085

- Venue: House of Textile Today

Background :

Weaving is a method of textile production in which two distinct sets of yarns or threads are interlaced at right angles to form a fabric or cloth. Other methods are knitting, crocheting, felting and braiding & plaiting. The longitudinal threads are called the warp and the lateral threads are the weft or filling .The method in which these threads are inter-woven affects the characteristics of the cloth .Cloth is usually woven on a loom, a device that holds the warp threads in place while filling threads are woven through them. A fabric band which meets this definition of cloth (warp threads with a weft thread winding between) can also be made using other methods, including table weaving, back start, or other techniques without looms.

The way the warp and filling threads interlace with each other is called the weave. The majority of woven products are created with one of three basic weaves: plain weave, satin weave or twill. Woven cloth can be plain (in one color or a simple pattern) or can be woven in decorative or artistic design.

Weaving is used to manufacture textile fabric .Fabrics are created through crossing of several parallel warp threads with the weft threads. The threads may be made of synthetic fibres , such as polyamide , polyester or aramid but also of cotton ,glass,wire or other raw materials.The basic principle of fabric has been established for centuries.

Now at this moment , China wants to reduce the environmental pollution from their textile industry. Many textile industry has already been shut down. Garments order is reducing in China day by day . Bangladesh needs to catch these orders . So, we need to achieve standard quality in woven fabric Production. The target of Bangladeshi entrepreneurs is the get the orders rejected by China . For this reason they must have achieve the standard in fabric production. They need efficient professionals at different stage of production. The objectives of the Training of Weaving & Weaving processing is to provide knowledge support to the Trainees so that they will be able to prove themselves valuable to the industry .

Course Contents :

- Types of fibre , Fibre parameters , usage , processing & other details .

- Types of yarn.

- Yarn production processes ,techniques used in Bangladesh spinning industry .

- Discussion on yarn parameters & the control techniques & its impact on weaving.

- Costing of Yarn

- Principles of weaving

- Constructional design of Weaving & woven fabrics

- Colour and weave effects

- Fabric analysis

- Nonwoven fabrics – different processes – bonding techniques

- This course will expose the students to the world of fabric decoration, weaving, its history and development over the years.

- Introduction to the basic elements of design as applied in decorative textile design. Practical exploration of, the line as a critical element in fabric decoration. Theoretical discussion into the qualities of line; straight curved, zigzag, wavy, broken etc to find out how they are applied in textile design.

- Weaving modification techniques .

- Weaving loom technique.

- Typical fault condition & fault finding procedures.

- Costing of a fabric .

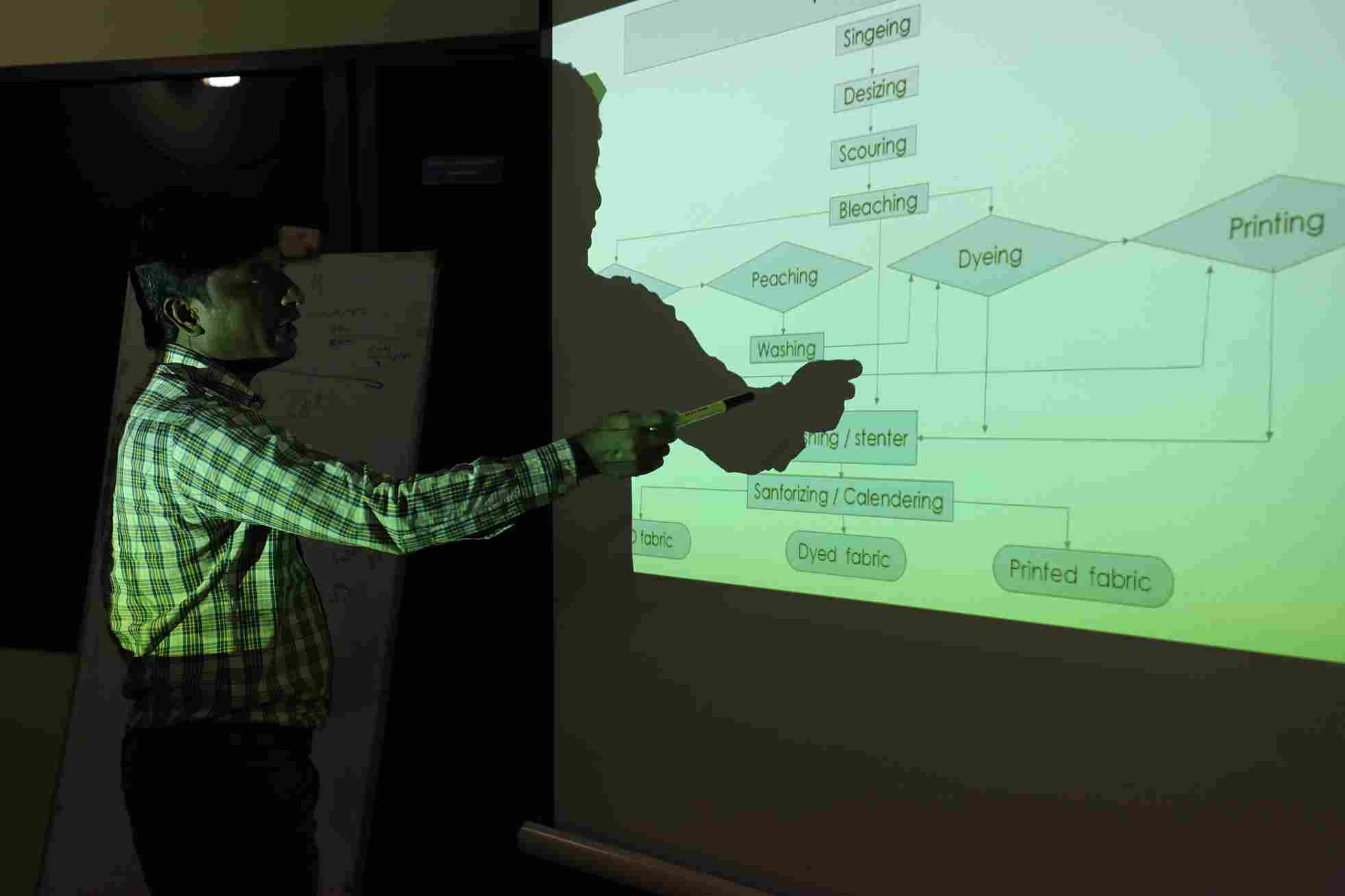

- woven Dyeing Techniques .

- Woven Dyeing critical points

- Woven Dyeing costing details

- Different test parameters & procedures .

- Trouble shooting .

Participants:

Owner, Director, GM, Managers, Executives, Students.

Methodology

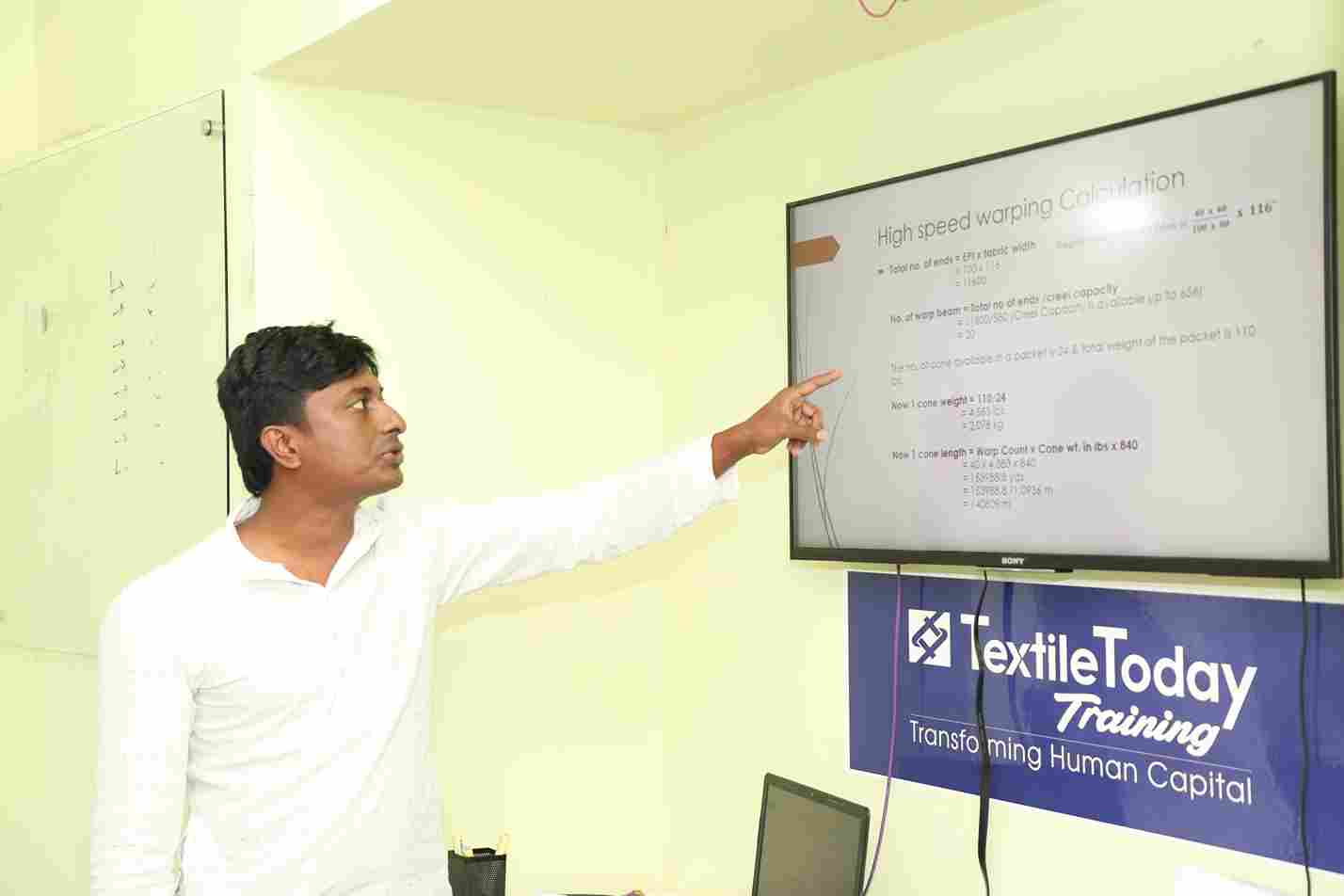

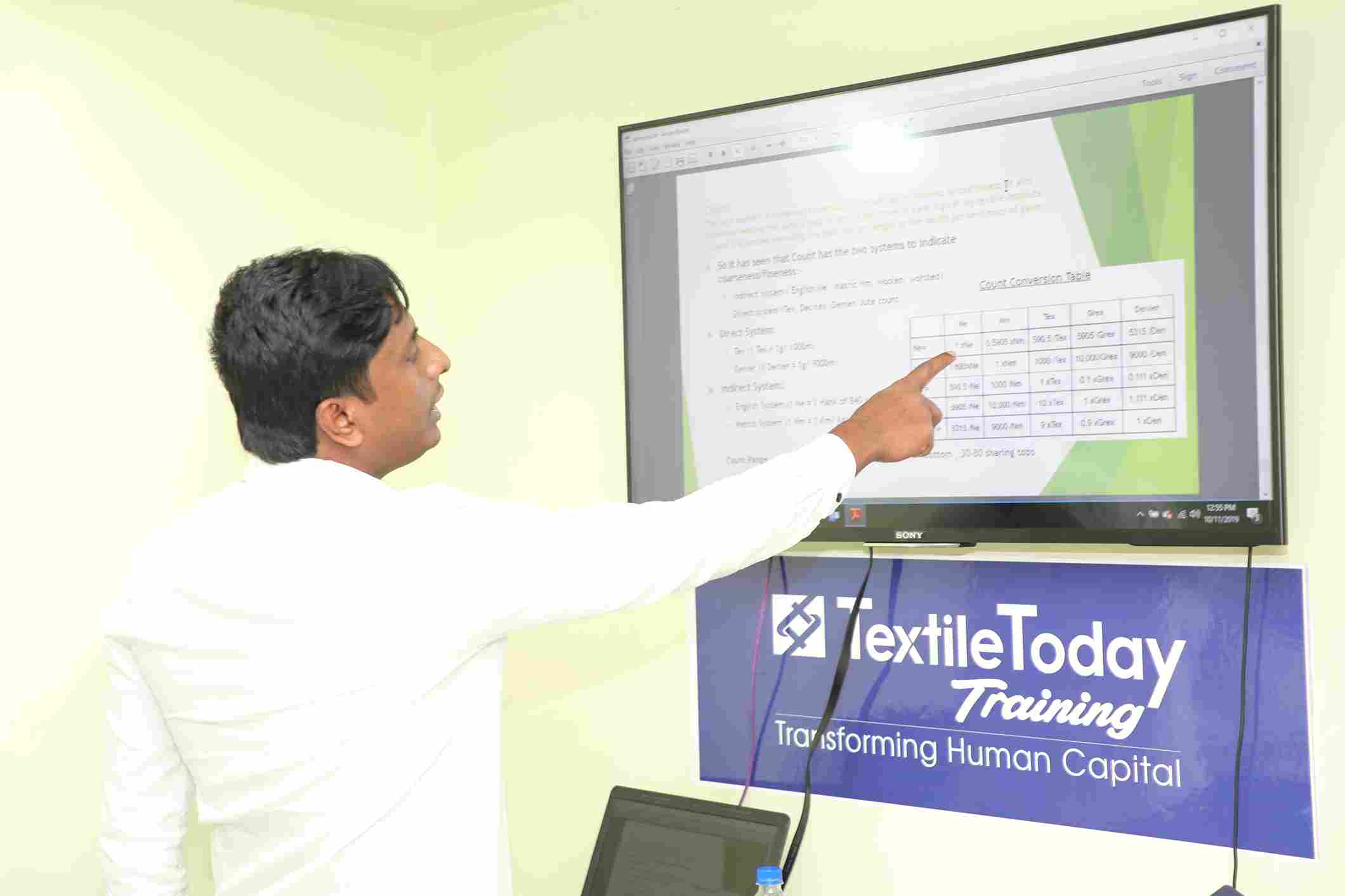

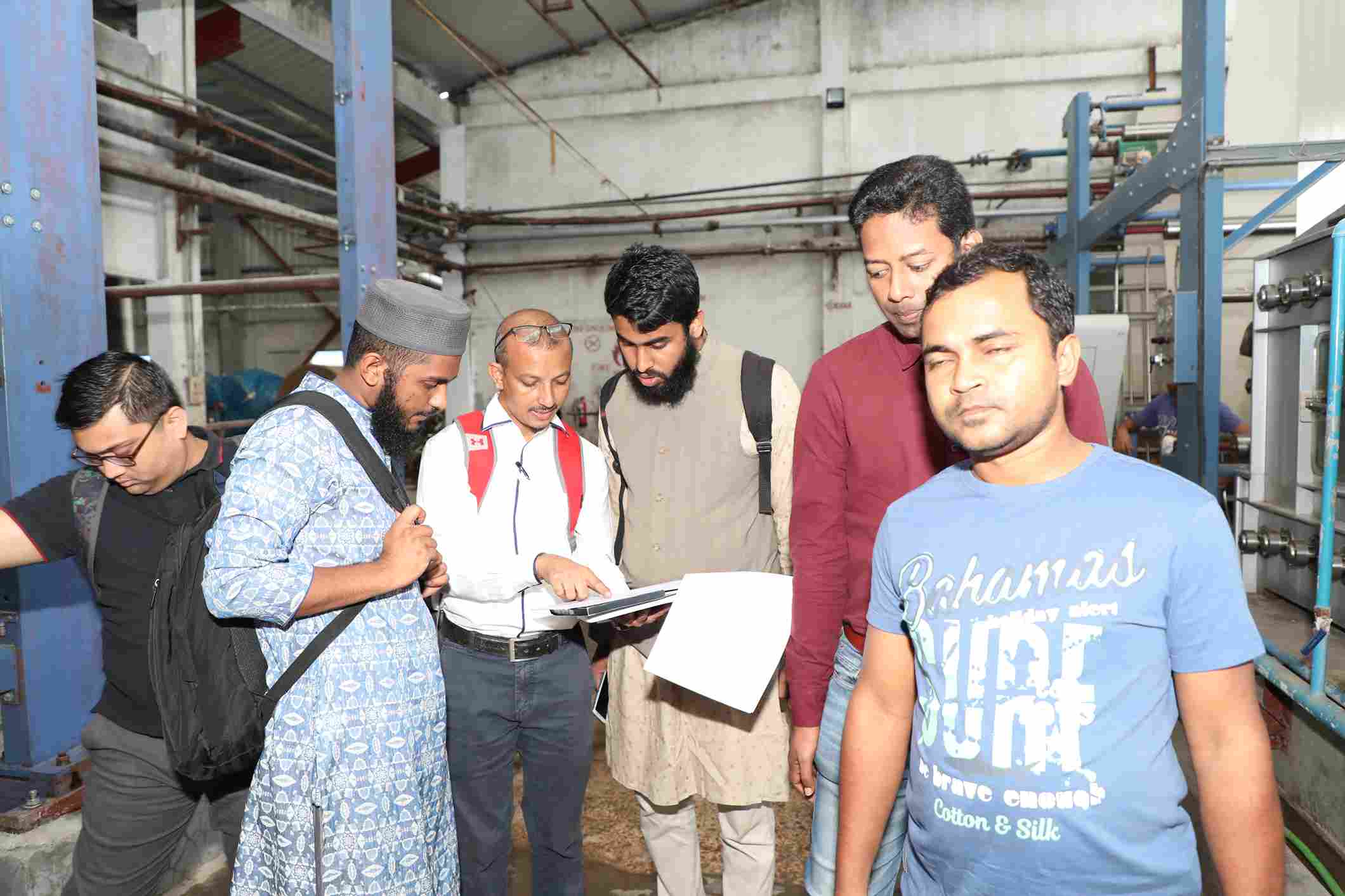

PowerPoint Presentation, Exercise, Question and Answer session.

Boarding

Course materials and food will be provided by Textile Today.

Certificates will be awarded to participants at the end of training.

Course Fee :

For individual training modules: 5900/- (Five thousand Nine Hundred taka only)

List of Successful Certificate Receivers

1st Batch

Displaying 1 – 11 of 11

Name Company

Abdullah Al Mamun

BUFT

Md. Arafat Hasan

BUFT

Sahabuddin Shihab

BUFT

Md. Sanuardi Mithun

Mukashi Associates Ltd.

Zubayer Hossain

Skyros Trading

Utpal Das

Skyros Trading

Mahbubur Rashid

Skyros Trading

Md. Mahmudul Hasan

Niter

Md. Musfiqur Rahman

Niter

Syeda Mahbuba Afroz

Niter

Md. Ashek Billah

Niter

2nd Batch

Displaying 1 – 8 of 8

Name Company

Mr. Ali Azzam Shimul

Mr. Rubaet Tanvir

Mr. Rabbani

Mr. Fakruddin

Mr. Mazharul

Sigbatullah

Shakil

Monjur Hasan

3rd Batch

Displaying 1 – 8 of 8

Name Company

Riazul Momen

Nice Denim Mills Ltd

Sajal Hasan

SKETC

Rahmatul Ahad Dipto

Nice Denim Mills Ltd

Md. Shihad

AUST

Nayan Bhowmick

Ovs Hong kong sourcing Ltd.

Binoy

NZ Group

Ashraful Alam

CTET

Mr. Saiful

Nassa Group

4th Batch

Displaying 1 – 11 of 11

Name Company

Md. Sabuz Ahmed

Alaq limited

Nayan Bhowmick

Quality Control Manager

Syed Rashidul Islam

Laundry Industries Limited

(Envoy Group )

Subir kumar nondi

Sachin Das

BUFT

Imtiaz Majumder

An Australian Company

Md. Saydur Rahman Miazi

DIU

Afsar Uddin

BUFT

Md. Tasnimul Hasan

BUTEX

Sudipta Bain

Uttara University

Hasan Mohammad Nishad

DIU

5th Batch

Displaying 1 – 8 of 8

Name Company

Mahmodul Hasan

BUBT

Tohiduzzaman Tonmoy

BUFT

Shihab Rahaman

BUFT

Suchen Dewan

BUBT

Mizanur Rahman

Sinfa Quality Garments

Abir Afnan

Lalmatia Mohila College

Mohammad Emadur Rahman Shakil Khan

Lyrics

Kaes Mahmud

Perry Ellis International

6th Batch

Displaying 1 – 10 of 10

Name Company

Mokter Hossain

BUFT

Mst. Masia Sahjabin

BUFT

Abdullah Al Bishal

BUTEX

Md Tanjim Alam Tayiab

AVP

Fahima Islam

Deputy General Manager (Souring)

Fakhrul Islam

Professional

Boshistho Acharjee Ratul

STEC

Rafiul Islam

Cloth Carnival ltd

Rajib Saha

Bozzetto (former employer)

Mushfiqur Rahman

Texebo Buying House

7th Batch

Displaying 1 – 10 of 10

Name Company

Noor- E- Nabi

BUFT

Mst. Masia Sahjabin

BUFT

Shahriarul Islam

BUTEX

Md. Nafis Kamal Alif

BUTEX

Naimul Islam

Panacia Clothing LTD

Nusrat-E-Noor (Annana)

BUBT

Shariar Hasan

BUTEX

Nazmur Rabbani

CTEC

Saqlain Mostak

CTEC

Sajjad Hossain Khandaker

BUFT

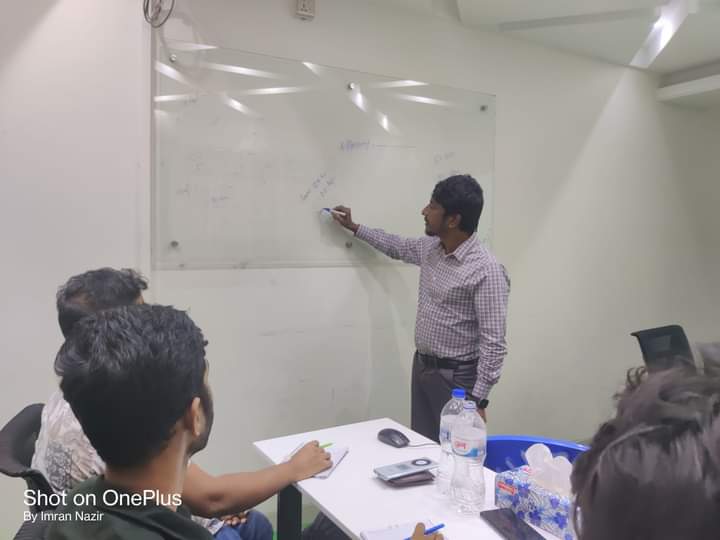

Some Previous Clicks

1st Batch

2nd Batch

3rd Batch

5th Batch

6th Batch

7th Batch