- This event has passed.

PPI Workshop on ‘Continual Improvement Kaizen’

October 28, 2022 - November 2, 2022

Event Navigation

PPI Workshop on ‘Continual Improvement Kaizen’

Important Dates & Time:

- Date:27th April,2018

- Time: 9.00am-1.00pm

- Last Date of Registration: Limited Seat (First come first serve basis)

- Contact: +88 01734 211085

- Venue: The House of Textile Today, 25A (2nd Floor), Lake Drive Road, Sector 7, Uttara, Dhaka-1230

Introduction

Continual improvement, or Kaizen, is a method for identifying opportunities for streamlining work and reducing waste. The practice was formalized by the popularity of Lean / Agile / Kaizen in manufacturing and business, and it is now being used by thousands of companies all over the world to identify savings opportunities.

Indeed, ‘Kaizen’ is a Japanese management technique renowned for improving organizational performance. The Japanese miracle in transforming the war ruined country to an economic giant within a short span of time is attributed to this unique approach of concept and the techniques.

Kaizen is a continual improvement initiative in increasing efficiency of performance. It contributes towards cost reduction and improvement of productivity and quality.

‘Kaizen’ develops a mind-set for continual improvement and brings the members in the organization to assume responsibilities in improving their work performance. Organizations adopting these techniques can achieve their goal successfully.

Objective

The ultimate aim of this workshop is to enable the participants to implement small changes in the organization for improvement. The Workshop deals with ‘Kaizen’ techniques. At the end of the workshop the participants will be able to:

- Explain the concept of ‘Kaizen’

- Identify different steps for implementation of Kaizen

- Describe relevant problem solving tools for Kaizen

- Prepare Action Plan for implementing ‘Kaizen’ in their respective workplace.

Benefits

- Participants can contribute in the continual improvement of the organization.

- Participant will be able to improve efficiency level of organization.

- Participant will be able to minimize seven LEAN wastes.

- Participant will be able to reduce costs.

Who can attend?

- Senior, Mid and Junior level executives

- Businessman- garment factory

- Officials engaged in T&C and Buying House

Methodology & Aids

PowerPoint Presentation, Group Study, Exercise and Q & A

Boarding

Course materials and food will be provided by Textile Today.

Certificates of appreciation will be awarded to participants at the end of workshop.

Course Fees

BDT 990/- (Nine Hundred Ninety Taka Only)

**BDT 700/- (Seven Hundred Taka Only) for TTH Alumni

2 workshop free per year for Textile Today Subscriber

2 or more participants from one organization will get special discount

Course Fee :

BDT 990/- (Nine Hundred Ninety Taka Only)

**BDT 700/- (Seven Hundred Taka Only) for TTh Alumni

**2 workshop free per year for Textile Today Subscriber

**2 or more participants from one organization will get special discount

Book Your Seat

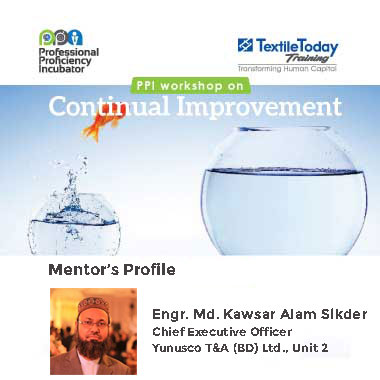

Mentor’s Profile

Engr. Md. Kawsar Alam Sikder

Fariha Knit Tex Ltd.

Asrotex Group

Trainer & Consultant in Continual Quality Improvement

■Having more than 19 years of successful professional track record with multitude experience along with 11.5 years in Knitting, 6.5 years in Knit Fabric Manufacturing & 1 year in whole supply chain i.e. yarn to ship.

■ Obtain training on Total Quality Management from Japan, also implement few tools like 5S, Kaizen, SMED, Quality Circle etc in few companies.

■ Obtain Lean Six Sigma Black Belt certificate. Implement few tools & techniques in few factories.

■ Keen interest to minimize process cost & re engineering the process to enhance manufacturing excellence.